Forestry and Fiber Sourcing

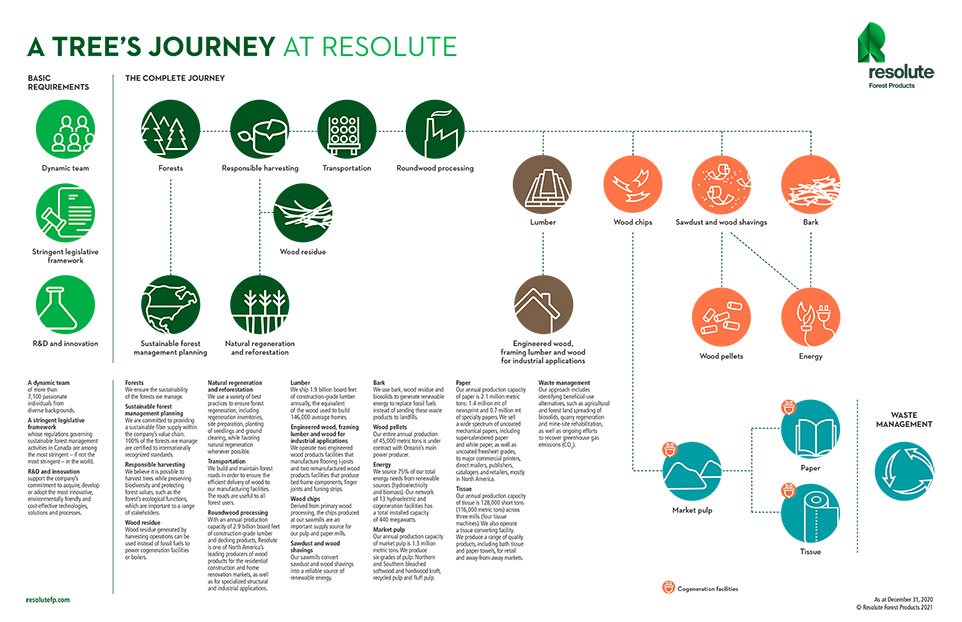

Resolute Forest Products’ commitment to producing quality products that meet the criteria of today’s environmentally conscious stakeholders begins with responsible fiber sourcing. This includes the sustainable management of forests entrusted to our care, careful tracking of wood fiber sources, and the use of recycled fiber.

Our ongoing commitment to transparency and annual sustainability reporting includes disclosing our forest management performance to CDP, a globally-recognized, non-profit framework that has long championed environmental disclosure as standard business practice. In 2022, Resolute received a B score for our forests disclosures to CDP. The management-level score is reflective of our coordinated actions on forest issues, including managing harvest risk and implementing monitoring programs. For more information, visit our 2023 CDP report on forest management.

Certification at a Glance

Forest certification and fiber tracking help to ensure the sustainability of our fiber supply and other forest values, including biodiversity conservation and ecosystem services. Strict adherence to internationally recognized forest management and chain of custody (CoC) standards provides our customers with the assurance that the wood fiber we utilize originates from responsible sources. For details about our certified operations, visit the Certification by Operation page.

Here are some of the highlights of our work in sustainable forest management and wood fiber sourcing:

- 100% of the woodlands we manage are third-party certified to internationally recognized independent certification standards: Sustainable Forestry Initiative® (SFI®) and/or the Forest Stewardship Council® (FSC®)

- 100% of Resolute’s manufacturing facilities have a CoC tracking system compliant with SFI®, FSC® and the Programme for the Endorsement of Forest Certification (PEFC), all of which require that 100% of the fiber processed meets minimum due diligence requirements related to risks of illegal logging and other important sustainability issues.

- 88% of the wood supply for sawmills and 56% of virgin wood fiber inputs for pulp and paper mills are certified to internationally recognized standards (not including our U.S. sawmills).

We recognize that the long-term future of our company and the communities in which we operate depends on sustainable management of the natural resources in our care and the performance of our operations. That is why we are deeply committed to managing the forest responsibly for future generations. We value wood as a renewable, high-quality, reliable and environmentally friendly raw material for our paper, pulp and wood products. Our Wood and Fiber Sourcing Policy, applied in conjunction with our 100% chain-of-custody-certified tracking systems helps manufacturers and traders avoid timber and timber products from unacceptable sources.

Our long-term commitments include maintaining internationally recognized forest management standards at 100% of Resolute-managed woodlands, as well as Coc certification at 100% of our manufacturing facilities. We have also set a 2026 target to increase externally sourced fiber that is third-party certified to 75%.

Where Does Our Wood and Virgin Fiber Come From?

- Crown land in Canada on which we hold harvesting rights, volume commitments, short-term volume allocations and auction sales

- Purchases from private forest landowners in Canada and the United States

- Wood chips from Resolute sawmills and from external suppliers

- Property the company owns or leases

Most of the virgin fiber consumed by our operations in Canada is sourced from Resolute’s managed forests. For our operations in the United States, much of the fiber is sourced externally through a supplier network of small, non-industrial private forest landowners. We work continually with suppliers and industry trade associations to encourage these landowners to certify their properties to forest management standards that are designed specifically for them, such as the American Tree Farm System® (ATFS).

SOURCING OF WOOD – CANADIAN SAWMILLS

| |

2020 |

2021 |

2022 |

| Total Fiber sourced (m3) |

7,774,356 |

8,155,314 |

7,808,813 |

| Proportion of virgin fiber (%) |

100.0 |

100.0 |

100.0 |

| Proportion of recycled fiber (%) |

N/A |

N/A |

N/A |

| Proportion of virgin fiber consumed with forest management certification (%) |

90.5 |

90.3 |

87.7 |

| Proportion of total virgin fiber supply sourced through SFI sourcing requirements, PEFC due dilligence or FSC controlled wood (%) |

100.0 |

100.0 |

100.0 |

SOURCING OF WOOD – U.S. SAWMILLS

| |

2020 |

2021 |

2022 |

| Total Fiber sourced (m3) |

1,090,961 |

1,348,377 |

1,496,165 |

| Proportion of virgin fiber (%) |

100.0 |

100.0 |

100.0 |

| Proportion of recycled fiber (%) |

N/A |

N/A |

N/A |

| Proportion of virgin fiber consumed with forest management certification (%) * |

0 |

0 |

26.0 |

| Proportion of total virgin fiber supply sourced through SFI sourcing requirements, PEFC due dilligence or FSC controlled wood (%)* |

0 |

0 |

100.0 |

* Resolute is committed to integrating its three U.S. sawmills into the company's multisite chain of custody certification in 2022

|

SOURCING OF VIRGIN AND RECYCLED FIBER – PULP, PAPER AND TISSUE MILLS

| |

2020 |

2021 |

2022 |

| Total Fiber sourced (odmt) |

4,407,967 |

3,938,021 |

3,301,132 |

| Canada |

2,587,004 |

2,383,045 |

2,340,721 |

| United States |

1,820,963 |

1,554,976 |

960,412 |

| Proportion of virgin fiber (%) |

96.3 |

94.9 |

95.7 |

| Proportion of recycled fiber (%) |

3.3 |

5.1 |

4.3 |

| Proportion of virgin fiber consumed with forest management certification (%) |

43.5 |

52.3 |

56.1 |

| Proportion of total virgin fiber supply sourced through SFI sourcing requirements, PEFC due dilligence or FSC controlled wood (%) |

100.0 |

100.0 |

100.0 |

Sustainably Managing Forests

The vast majority of the forests we manage are in Canada, where principles of sustainable forest management are used to balance environmental, social and economic objectives. Canadian forest products companies operate in a highly regulated environment with active enforcement by federal, provincial and local government partners. In fact, the Canadian boreal forest is one of the world’s most highly regulated forests. Furthermore, Canadian forest products companies and consumers benefit from numerous conservation activities such as sound protected-area development and collaborative forest management strategies.

In Canada, as required by provincial laws and regulations, 20- or 25-year forest management plans are updated every five years in collaboration with government and other stakeholders. Public consultation is part of the planning process and critical for the development of collaborative forest management strategies, which ensure that social needs are satisfied and values are protected.

Our Forests Are 100% Regenerated

Less than half of one percent of Canada’s boreal forest is harvested each year – far less than what is disturbed annually by natural causes such as forest fires, insects and disease, and 100% of the woodlands we harvest are regenerated through natural and tree planting. The regeneration of harvested woodlands is an essential component of responsible and sustainable forest management. We rely on various forest management techniques and best practices, including regeneration surveys, site preparation, planting of seedlings and seeding – all in combination with natural regeneration.

For harvesting, we use various methods that have been employed sustainably for decades, including clearcutting. Clearcut harvesting is used because it generally increases regeneration success and subsequent tree growth. In some locations and circumstances, it is the only feasible method for creating the conditions required for regenerating stands. Clearcutting can also be used to further ecological objectives like improving wildlife habitat for species requiring high-density, even-aged stands, or encouraging species diversity. Harvested stands regenerate naturally and quickly or are replanted according to sustainable forest management practices.

Approximately 75% of the area harvested through forestry operations grows back naturally. The other 25% is promptly reforested via seeding or planting of seedlings. Responsibly managing timberlands, using wood before natural disturbances occur, and salvaging wood after natural disturbances have occurred can safeguard the forest’s natural life cycle and ensure its sustainability.

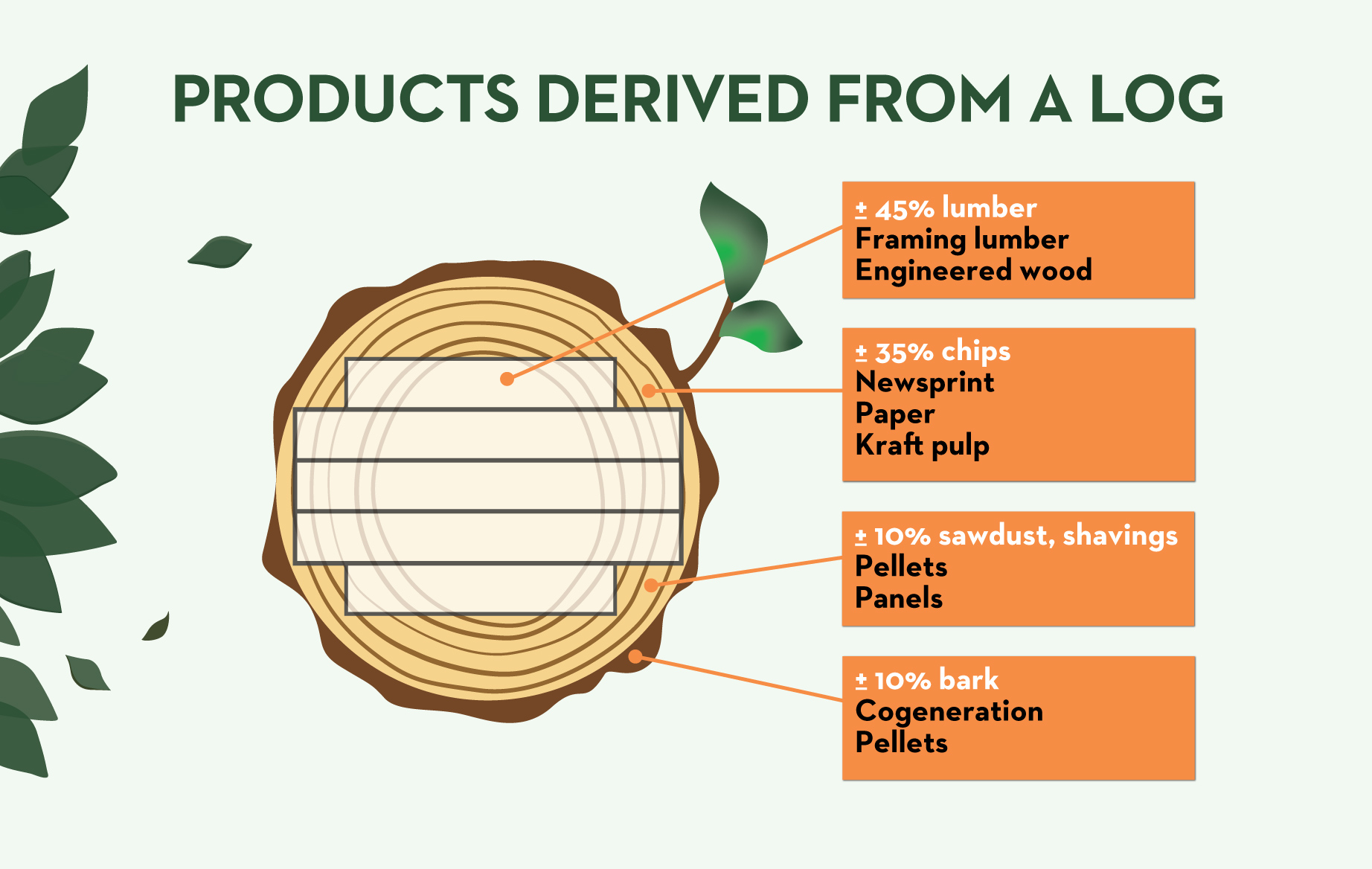

Optimizing Fiber Use

Our manufacturing facilities and processes optimize fiber use, reducing waste and creating value. Harvested trees are processed into lumber, mainly for construction or renovation of houses, which preserves the carbon accumulated in the wood for decades. Processing a log at a sawmill generates by-products, mainly wood chips, sawdust, shavings and bark. The bark is used to generate energy, while chips and other residues are used mainly to produce pulp and paper. Our wood remanufacturing facilities produce box spring components, finger joints, furring strips and I-joists, further ensuring optimal fiber use.

For the little waste that is left, we identify beneficial-use alternatives, such as agricultural land spreading, reducing what we send to landfills. For more information on our waste management initiatives, visit our Key Performance Indicators page.

PDF version